A Quick Refresher on Sterilizing DryShield Mouthpieces

What You Should Know: Cleaning, Sterilization and Maintenance

The DryShield DS1 is made from a high heat-tolerant material, and the DryShield mouthpiece is made of an autoclavable silicone material. All DryShield components are completely autoclavable. DryShield recommends following standard infection control protocols for sterilization.

- After completion of dental procedure, DryShield recommends running the DryShield DS1 with a non-corrosive, pH neutral enzymatic cleaning

solution and performing a surface disinfection with a disinfectant wipe between each patient. Users have the option to sterilize the DryShield DS1. - Maintenance of the lever o-ring is done through visual inspection. Replace o-ring when lever function decreases.

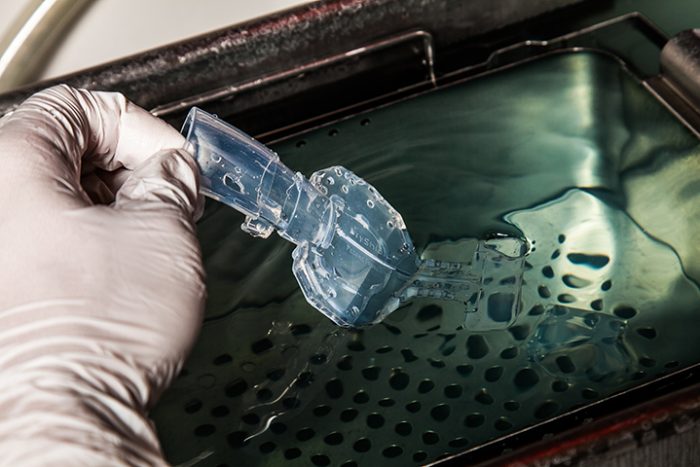

- After completion of each dental procedure, detach mouthpiece from bite block and place both in ultrasonic cleaner for 15 minutes.

- Next, clean the separated mouthpiece and bite block of debris by thoroughly scrubbing with soap and water or a detergent solution.

- Clean the inside of the mouthpiece through access at the slit opening and at the suction connector region using a long-handled brush and thorough scrubbing.

- Then, rinse under running water, air dry and place in autoclave pouch to be sterilized.

- The DryShield Mouthpiece MUST BE sterilized between each use. Sterilize in a steam autoclave machine at minimum 121 °C (250 °F) for a minimum of 30 minutes. Allow a minimum of 30 minutes in drying cycle.

The sterilization parameters for the DryShield Mouthpiece are found below.

| Cycle Type | Parameter | Minimum Set Point |

|---|---|---|

| Gravity 250° F (121°C) | Exposure Temperature | 250° F (121°C) |

| Exposure Time | 30 minutes | |

| Dry Time | 30 minutes |

DryShield mouthpieces are autoclavable up to 50 times.

Print and Post in your Office Sterilization Area.